GFRP or Glass Fiber Reinforced Plastics

GFRP is like CFRP, the preferred material for engineers looking for ways to upgrade their product design. At Alformet, we apply UD-tape made from a thermoplastic matrix which is reinforced with glass fibers, that offer high strength and moderate stiffness while reducing weight of the component. The resistance against corrosion and chemicals, allows you to reduce maintenance costs and increase the life cycle time. Combined with 100% recyclability, GFRP based on thermoplastic resin offers the best of two worlds: metals and plastics.

Find out here why engineers across the world are upgrading products and processes with GFRP based on thermoplastic resin, saving costs while achieving sustainability targets!

What properties does GFRP based on thermoplastic resin have?

Alformet processes UD-tape from thermoplastics reinforced with glass fibers. The most valuable properties are:

- Lightweight (4 times lower than steel and 30% lower than aluminium)

- High strength and moderate stiffness; if you require high stiffness than carbon fibers should be considered (see CFRP)

- Corrosion and chemical resistant (reduced maintenance)

- Excellent damping characteristics

- High fatigue resistance

- High temperature formable: Suited for bending and reshaping

- 100 % recyclability

What are the different variations of GFRP based on thermoplastic resin?

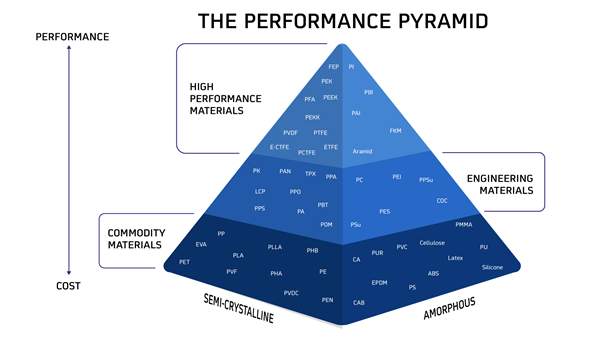

Virtually any combination of thermoplastic resin with glass fibers can be processed at Alformet. The most used combinations of glass fiber and thermoplastic resin are:

Why is GFRP better than steel and aluminium in engineering applications?

The high strength and stiffness of our material in combination with low weight gives you a head start when you look for process and product improvement opportunities. Certainly when you become aware that GFRP does not require surface treatment to protect your product against the impact of corrosion or even aggressive environments like sea water or chemicals. It has much better fatigue resistance than metals and also higher damping properties required for reduction of vibrations and better comfort; you have all you need with GFRP material.

Are GFRP tubes based on thermoplastic resin helping with sustainability goals?

The tubes that Alformet produces from thermoplastic based GFRP material are sustainable. The need to treat our natural resources with respect is met with these tubes produced by Alformet. The products and material fit in the 3R model: Reduce, Reuse and Recycle. And the applied production process in Alformet operates with renewable energy!

How do we manufacture thermoplastic based GFRP tubes for industrial purposes?

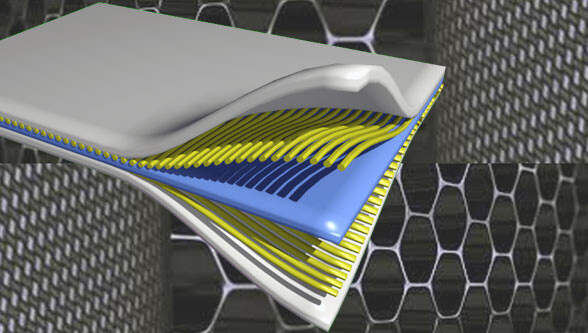

Alformet processes UD-tape made from a thermoplastic resin and reinforced with glass fibers, applying laser winding (LATW). The fast and efficient process produces layers of the tape delivering a tube with customer specific length, wall thickness and reinforcement direction in the material of choice. Watch the video of the process on the right!

We also perform additional fabrication: bending (reshaping) and machining of the tubes.

We would like to get in touch with you!

Are you interested but you still have some questions? Get in touch with us and we will work together to offer some ideas.

Call us at +31416235074 or fill in the form

Already know what you want?

Have you already specified your tube dimensions with material and load information? In that case we offer a design tool to specify the tube and receive a quotation.

Frequently asked questions

General

FRP material is a versatile material with high performance characteristics. It possesses valuable engineering properties, like high strength/stiffness combined with a low density. Additionally the durability, like for instance corrosion and chemical resistance, is another characteristic that favors the application of FRT in engineering challenges.

FRP is also called CFRP when the reinforcement is carbon fiber material and GFRP when glass fibers are used.

The ‘P’ in ‘FRP’ stands for Polymer or Plastic. Alformet uses only Thermoplastic material reinforced with fibers. Thermoplastic material has the advantage of being 100% recyclable and contributes to the transition to a circular economy.

The word plastic is the common name for synthetic polymer, so there is no difference if you refer to synthetic material. There are three types of polymers: thermoset, thermoplastic and elastomer.

-

Thermoset is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin)

-

Thermoplastic, or thermosoftening plastic, is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

-

An elastomer is a polymer with viscoelasticity (i.e., both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials.