Anwendungen und Märkte

Thermoplastische Verbundrohre können in vielen Bereichen eingesetzt werden und wir sind davon überzeugt, dass viele konstruktive Elemente prinzipiell aus thermoplastischem Faserverbundmaterial hergestellt werden können. Auffällige Beispiele sind Fahrradrahmen, Lenkachsen, Lager, Buchsen und Dichtungen – alles typische Komponenten, die unter hoher Belastung eingesetzt werden und deren Lebensdauer durch den Einsatz moderner Materialien und deren fortschrittlichen Eigenschaften verlängert werden kann. Darüber hinaus können andere Belastungsbedingungen wie Chemikalien und Korrosion ohne Probleme mit thermoplastischen Verbundwerkstoffen toleriert werden.

Profitieren Sie sofort von Gewichtsreduzierung, verbesserter Produktleistung, Haltbarkeit und Recyclingfähigkeit, indem Sie Ihr Design optimieren. Die Nutzung von thermoplastischen Verbundrohren bietet die Möglichkeit, das volle Potenzial Ihres Produkts auszuschöpfen!

Es gibt viele Beispiele für Märkte, in denen unsere endlosfaserverstärkten thermoplastischen Rohre einen erheblichen Mehrwert gebracht haben. Nutzen Sie diese Übersichten, um sich für neue Ideen inspirieren zu lassen.

Maschinen und Anlagen

Typisch für dieses breite Marktsegment sind Produkte und Komponenten, die hohen Belastungen ausgesetzt sind und einem hohen Verschleiß unterliegen.

Beispiele: Förderrollen (Material- und Warentransport), Antriebsstränge sowie Pneumatik- und Hydraulikzylinder.

Industrie

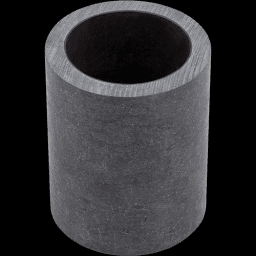

Thermoplastische Verbundbauteile werden zunehmend im industriellen Umfeld eingesetzt und eignen sich ideal für Dichtungen, Lager und Buchsen. Unsere thermoplastischen CFR-Rohre bieten hervorragende Leistung, wenn eine längere Lebensdauer wichtig ist.

Auch Verfahren wie das „Overmolding“ oder das Aufbringen von „Inserts“ in Spritzgussprodukte werden in vielen Branchen eingesetzt, wo die Eigenschaften von CFR-Thermoplasten große Verbesserungen und Vorteile bringen.

Automotive (inkl. Kleintransporter)

Der Automobilmarkt steht vor vielen Herausforderungen, bei denen aufgrund von Emissionsanforderungen zunehmende Beschränkungen auferlegt werden. Die Elektrifizierung von Fahrzeugen und Transportbeschränkungen in Ballungsgebieten werden Veränderungen sowohl im Fahrzeugbau als auch im Getriebe vorantreiben. Diese Veränderungen erfordern den Einsatz leichterer, leistungsfähigerer Materialien und Komponenten, wie beispielsweise unserer faserverstärkten thermoplastischen Rohren.

Beispiele: Lenkung, Elektromotor und Antriebswelle

Offshore - Marine - Schiffbau

Obwohl dieser Markt selbst sehr vielseitig ist, ist das aggressive Umfeld der wichtigste gemeinsame Faktor. Dies hat zu einem erheblichen Wartungs- und Reparaturservice in der Branche geführt, der viel Geld erfordert. Durch den Einsatz faserverstärkter thermoplastischer Produkte kann die Lebensdauer von Teilen erheblich verlängert und die Wartungskosten von Produkten, die unter solch rauen Bedingungen eingesetzt werden, stark reduziert werden.

Beispiele: Elemente (zB Handlauf) auf Öl- und Gasplattformen und Bauwerke für Fischfarmen

Sport & Freizeit

Anlagen für Freizeit- und Sportaktivitäten sind perfekte Beispiele, bei denen sowohl Gewichtseinsparung als auch Festigkeit wesentliche Attribute jedes in ein Design integrierten Materials sind. Als Beispiel: Das Mehrgewicht des Akkus bei einem E-Bike soll durch leichtere und stärkere Rahmen aus faserverstärkten Thermoplastrohren ausgeglichen werden.

Beispiele: Fahrradrahmen und Fitnessgeräte.