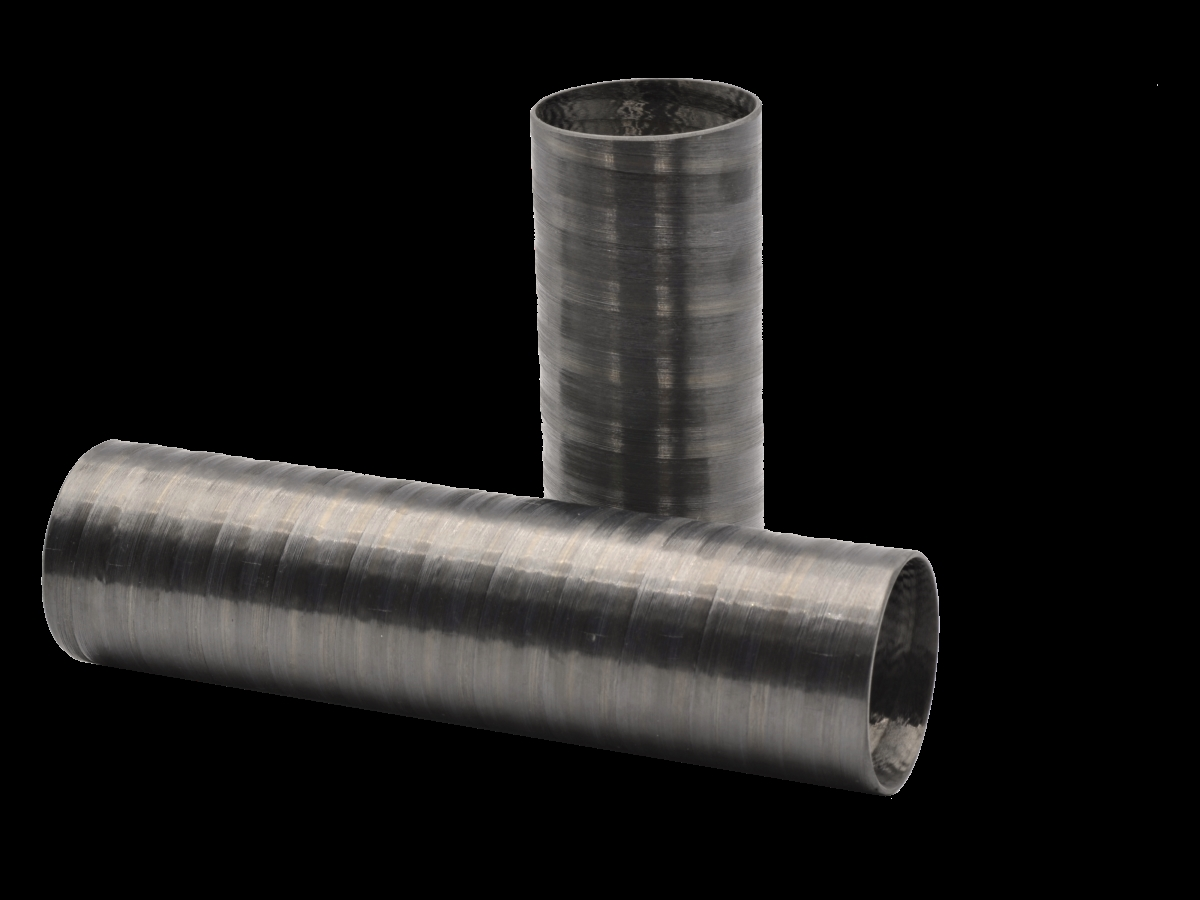

Carbon Tube / Carbon Fiber tube

Carbon tubes (full name carbon fiber reinforced thermoplastic tubes) are the solution for challenges where lowest weight with highest strength and/or stiffness are required. Carbon fibers have grown in popularity for numerous applications over recent years. The perfect combination of strong and lightweight carbon fibers in a protective thermoplastic resin, is a solution that fits in a sustainable world. Not only because of the durability of this material but most importantly because the material can be reused and recycled.

UD-tape with carbon fibers

With our laser assisted winding process, we produce bespoke tubes with customer specified diameters and lengths, from so called UD tape. UD tape consists of reinforcement fibers in a thermoplastic resin. While the fibers provide the strength and stiffness, the thermoplastic resin protects the fibers and provides chemical and corrosion resistance.

Other important advantages of carbon reinforced thermoplastic tubes are the high fatigue resistance and the high impact energy absorption capability (for example in crash worthiness testing). Furthermore, carbon fibers are able to conduct both electrical and heat energy.

Use our product configurator for your specification or contact us for more information!