CFR Thermoplastics

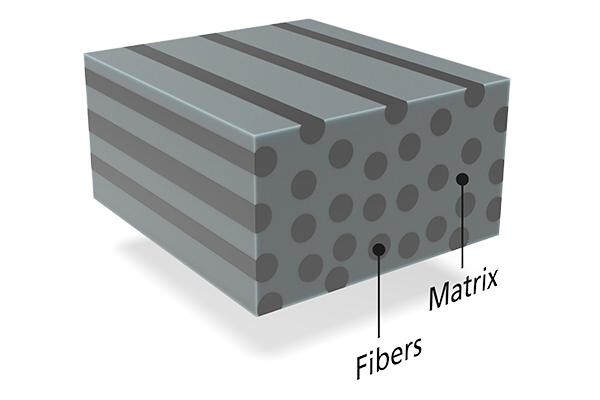

In this blog, I will help you in understanding the difference between the general term ‘composite’ and the more specific ‘cfr thermoplastics’ or in full 'continuous fiber reinforced thermoplastics'. Important here is that the continuous (or endless) fiber provides the optimal reinforcement for heavily loaded products.

The definition of ‘composite’, is actually a long existing term for the combination of two materials that bring new features, or advantages. It is actually not specifically related to polymers and fibers but can be any combination of materials or elements. For instance reinforced concrete (concrete with steel bars) is a composite material or a sandwich panel (like foam in between two layers of aluminium).

Thermoset composites

The development of reinforced polymers started with the combination of fibers and thermosetting polymers (mostly called thermosets). Thermoset is a polymer that is irreversibly hardened by curing from a soft solid or viscous liquid prepolymer or resin. The liquid resin is, due to the relative low viscosity, perfectly suited to be laminated together with fibers and molded into a specific shape: the thermoset composite product. As stated this process is irreversible, which means the material cannot be changed in form or shape and it is therefore not (easily) recyclable. The alternative to burn thermoset products in incinerators results in limited energy generation and sometimes toxic gases and fumes. That is compared to metal or thermoplastic material the biggest disadvantage of the application of thermoset materials.

Thermoplastic Composite

The development of thermoplastic composites has taken a long road because of the higher viscosity of thermoplastics compare to the resins of thermosets. Today’s manufacturing methods allow the production of many different type of UD-tape (Uni-Directional tape, with the fibers in one direction). A lot of different thermoplastic polymers can be combined with fibers and slitted in various width to form sheet or in small width for tape laying processing methods. The combination of layers in different angles make it possible to optimize the strength direction or to create quasi-isotropic behavior of the final product.

Slitted UD-tape (© Mitsui Chemical)

CFR Thermoplastic material

The tape and sheet are the raw material for further processing with thermoforming, tape laying or tape winding. The fiber in the UD tape is endless and that is why the products made of UD tape are called 'continuous fiber reinforced thermoplastics' (CFR Thermoplastics / CFR-TP) and offer the full strength of the endless fibers in demanding applications.

Thermoplastic material becomes softer at a certain temperature that depends on the type of material. In those applications where the operating temperature is very high, materials such as PEEK (or PAEK and PEKK) can offer a solution. Thermoplastics can be formed (locally) by bringing the temperature well above the glass temperature (Tg) and deforming the material (like most metals). Equally important to mention is the recyclability of thermoplastic composite material, which means that the material fits in the circular economy!

Written by Theo Mimpen (March 2021)

Image: Offshore solar panel farm

Frequently asked questions

General

FRP material is a versatile material with high performance characteristics. It possesses valuable engineering properties, like high strength/stiffness combined with a low density. Additionally the durability, like for instance corrosion and chemical resistance, is another characteristic that favors the application of FRT in engineering challenges.

FRP is also called CFRP when the reinforcement is carbon fiber material and GFRP when glass fibers are used.

The ‘P’ in ‘FRP’ stands for Polymer or Plastic. Alformet uses only Thermoplastic material reinforced with fibers. Thermoplastic material has the advantage of being 100% recyclable and contributes to the transition to a circular economy.

The word plastic is the common name for synthetic polymer, so there is no difference if you refer to synthetic material. There are three types of polymers: thermoset, thermoplastic and elastomer.

-

Thermoset is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin)

-

Thermoplastic, or thermosoftening plastic, is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

-

An elastomer is a polymer with viscoelasticity (i.e., both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials.