Machine & Equipment

Machine and equipment engineering is one of the most diverse markets for application of CFR Thermoplastic tubes, particularly products or components that have to operate under heavy load conditions and are high maintenance. This includes many different parts, shapes and functions – of which some examples are presented below:

Construction

CFR Thermoplastic tubes as part of machine construction combines lightweight with strength and stiffness. The advantages in this application translate directly into accurate positioning due to minimal inertial effects of the moving parts. The arms of the so called ‘delta robots’, used for pick and place purposes, are great examples.

Delta robot (© Codian Robotics)

Conveyor System (© Lorbrand)

Pressure and Force Containment

High pressure containment in hydraulic cylinders are also the perfect setting to apply our CFR Thermoplastic tubes. Often used in combination with a metal or thermoplastic liner (inner tube), the reinforcement tube can easily withstand the forces being applied.

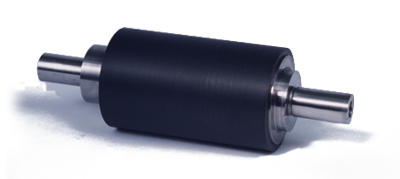

Rotor overwinds or rotor sleeves are the ideal examples of the application of CFR Thermoplastic tube material. The fiber reinforced thermoplastic rotor sleeve contains the (magnetic) elements on the rotor, simultaneously reduces the gap between rotor and stator and also prevents eddy currents (compared to metal), increasing the motor efficiency. The strong and thin walled CFR Thermoplastic tube has all those benefits in one solution!