Our raw material: UD-tape

The Laser Assisted Tape Winding (LATW) was developed to achieve controlled heating and solidification of the UD tape material during winding around a mandrel with high productivity and a high degree of automation. In this blog, I explain what UD tape is, how it is produced and what options are available on the market from UD tape suppliers. The flexibility in terms of product composition and dimensions as well as the wide range of offerings from many suppliers around the world offer advantages for you as an end user of these thermoplastic CFRP tubing products.

By the end of this blog, you will understand why Alformet's LATW technology allows you to choose the ideal combination of fibers and thermoplastics to achieve the desired properties and behavior of your product.

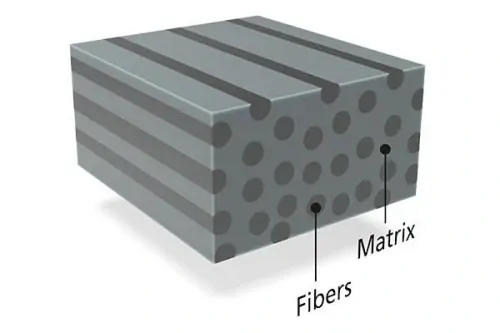

What is UD-Tape?

UD tapes are composite materials in which the fibers are impregnated in one direction and in a thermoplastic matrix. The tapes contain continuous fibers, the thermoplastic resin and the matrix of the tape enable welding processes and hot forming of the material.

The geometry of the tapes gives the designer additional degrees of freedom when designing the desired component. The fiber-reinforced tapes are used either on one side or on both sides of a component in sandwich form. They can also be processed into 2D and 3D grids or organo sheets, whereby the stiffness can be adjusted in any direction. They are also used for wrapping pipes and containers. Ideally, UD tapes give the component strength exactly where it is needed. Areas in the component that require (more) strength or stiffness can be reinforced locally. The reinforcements can transfer large forces, making the end products more efficient and resource-saving. As a result, components can carry more load even with thinner walls and in some cases without ribs.

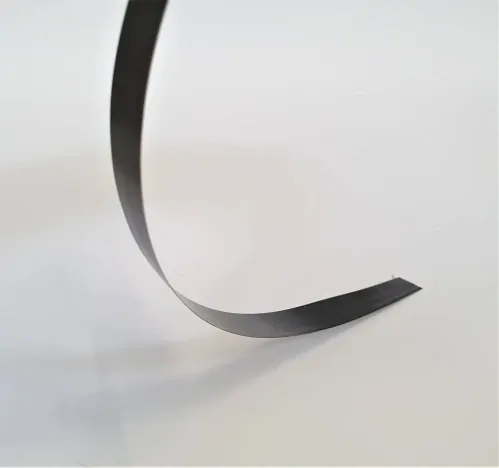

UD tapes are produced using special equipment that impregnates the fibers with a thermoplastic resin. In the production of UD tapes, a tape of a certain (standard) width and thickness is produced, which is then cut to the final width specified by the customer. Spools (or bobbins) containing the cut tape are available in various lengths for the production of organo sheets for thermoforming, coiled tubes(LATW)bent 3D sheets with LATP (Laser Assisted Tape Placement) etc. are available.

Combination of fibers and thermoplastics

The advantage of UD tapes lies in the flexibility of the material combination and the dimensions. Especially when combining thermoplastic matrix and reinforcing fiber, the current possibilities are very extensive and can and will be further expanded in the future. Basically, the task of the continuous fibre is to reinforce the component of the UD tape, and the task of the thermoplastic resin is to optimize the function of the fibre and add further properties, such as corrosion and chemical resistance, damping properties, energy absorption in the event of impact, etc.

Nowadays, UD tapes are made from a thermoplastic matrix of PE to PEEK and PP, PA (PA6, PA12 and much more), PC, PPS, PEKK, PAEK etc.

On the fiber side, glass and carbon fibers are most commonly used, but Kevlar/aramid, basalt and flax fibers are also available today for reinforcing UD tapes.

In the future, we can expect to see many more combinations of specific applications through to more sustainable materials with biopolymers and biofibers currently being developed. As you can imagine, the possibilities are endless and further announcements of new materials for lightweight products with high strength and stiffness can be expected.

All of these combinations meet the need for materials that can be recycled and reused. In addition, all these combinations can be processed with our laser technology (LATW and LATP), so you get the best of both worlds - thermoplastics and reinforcing fibers!

Written by Theo Mimpen (Mai 2022)